Laser-Aided Manufacturing

Nowaday’s, there are many ways to create models and prototypes. One of the most well-known technologies for manufacturing or prototyping is CNC Machining, which includes processes like milling, drilling, and turning. However, this technology is increased in rapid growth the usage and implementation of CNC system in industries and colleges but at greater cost. To reduce the cost and man power is Laser cutting and engraving introduced, especially additive processes, will be the foundation of production processes in the future.

Common Applications

Laser cutting and engraving is most often seen in industries that demand a lot of metal parts, including:

- Automotive

- Aerospace

- Medical

- Architecture

- Custom Manufacturing

- Custom Signage

Technology Solution

INOVAITEC offers advanced laser software that automatically generates laser tool paths (G-Code) for engraving, cladding, cutting, and hardening. The deployment of the INOVAITEC laser's high-performance user interfaces depends on the configuration of the respective system or machine. The software can load any image or vector drawing and send it to laser machining with a few clicks. Additionally, the software offers process parameters for each laser-aided process, geometrical simulation of the laser additive and laser cutting processes, and full collision avoidance with toolpath planning (and machine components) and automatic link motions between operational machining motions.

The advantages of the laser software:

- Suitable for many materials

- Users friendly (easy to use)

- High precision

- Minimal maintenance

- Ability to mark on diverse materials

- Save time and cost

The software supports a variety of file formats, including:

- DXF (AutoCAD Drawing Exchange Format)

- SVG (Scalable Vector Graphics)

- JPG, PNG, BMP, TIF, PGM, GIF

- PDF (Document Format)

- XV3 (3D-Format)

Machine file formats:

- GCode, MPF, NC (Numerical Control)

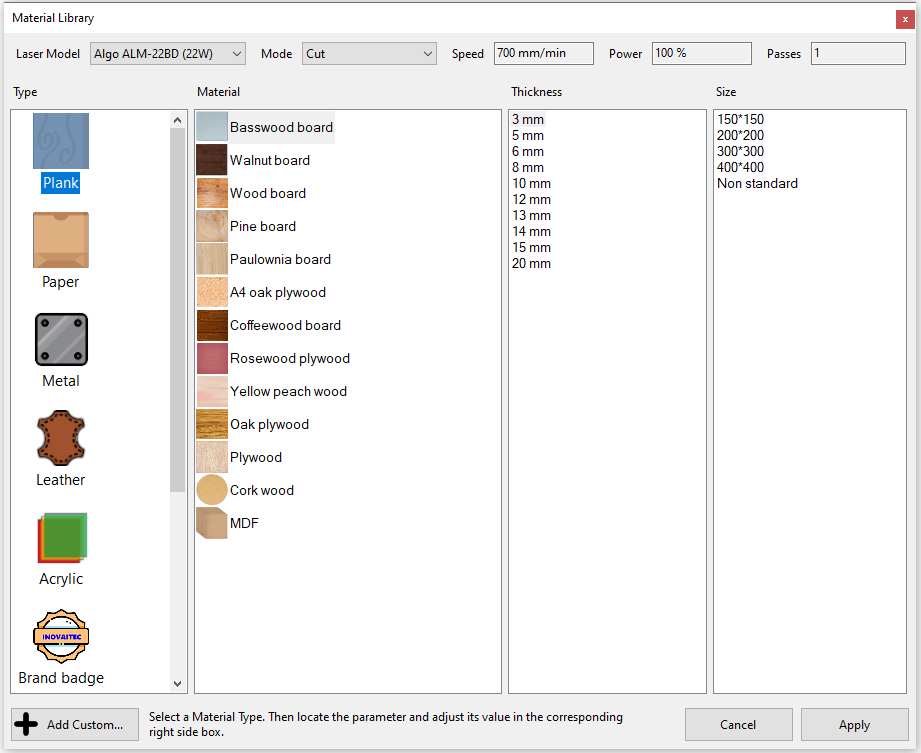

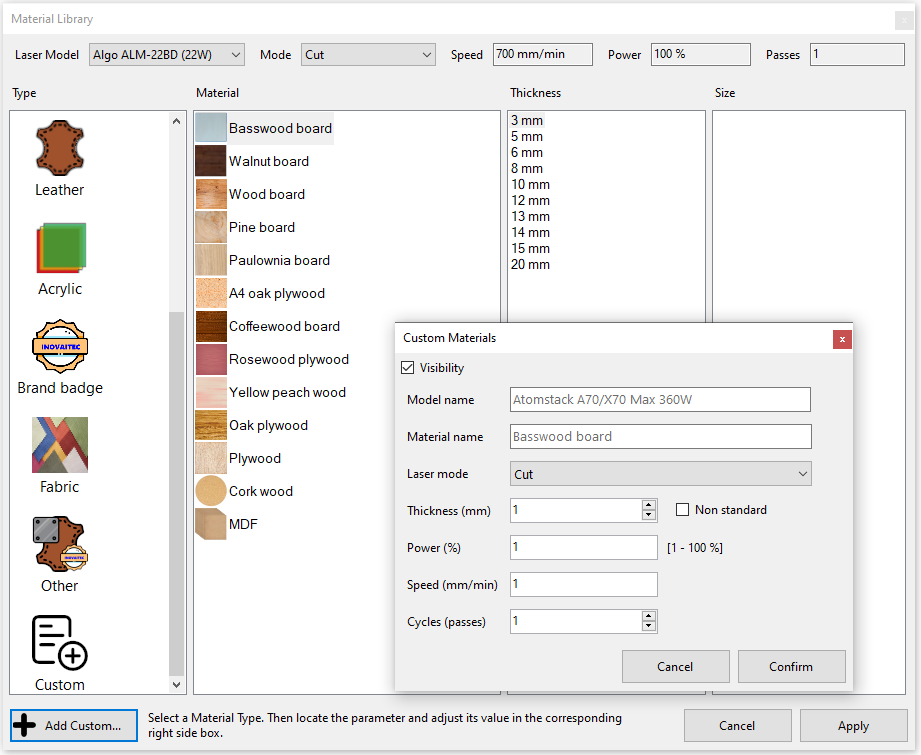

The software database includes a list of previously used laser machining processes and their parameters, all related to the selected materials such as metal, paper, and wood for engraving or cutting. Additionally, the software allows the machine operator to define new machines and their process parameters within in the software’s material library. This feature makes it easier for the user to find all the desired process parameters related to a specific material in the future by simply searching for the machine’s name.

Laser engraving and cutting are generally best for these materials:

- Metal

- Rubber

- Wood

- Leather

- Acrylic

User-Specified Parameters

DXF TO G-CODE

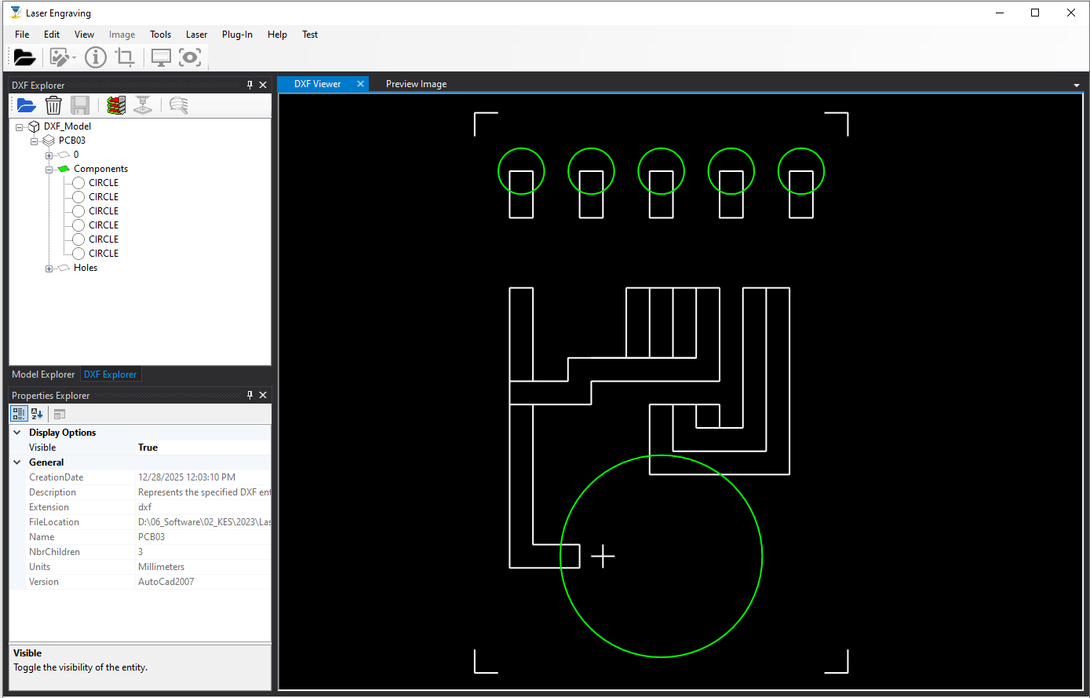

The INOVAITEC laser software supports all DXF and DWG versions, including ASCII and Binary formats. It allows users to view, edit, measure, and convert files.

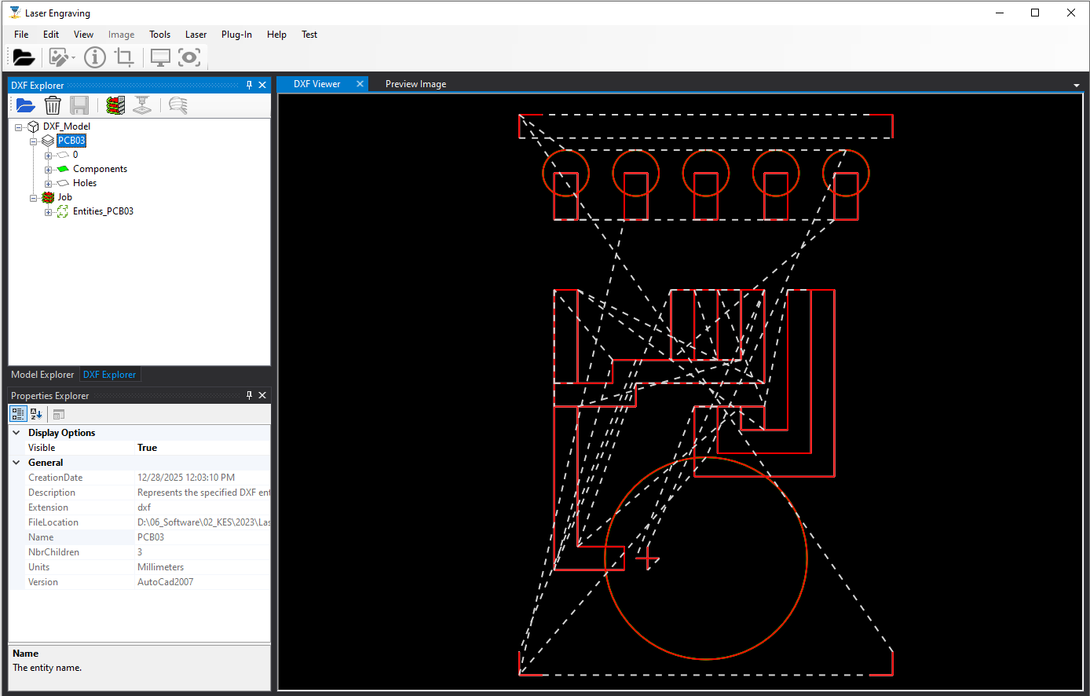

I - Load the DXF file and build its topology in the TreeView

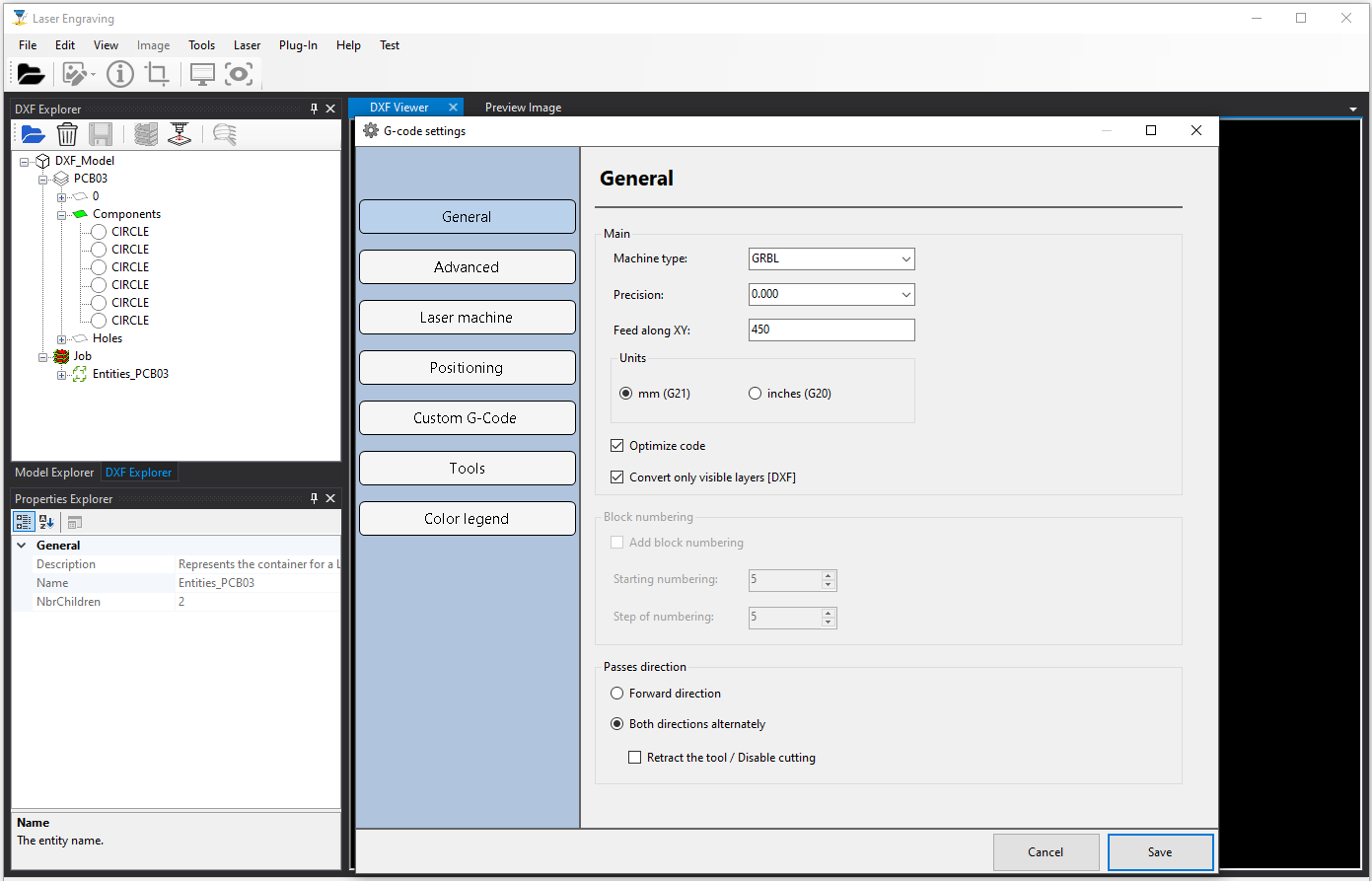

II - G-Code Settings

III - Convert To G-Code

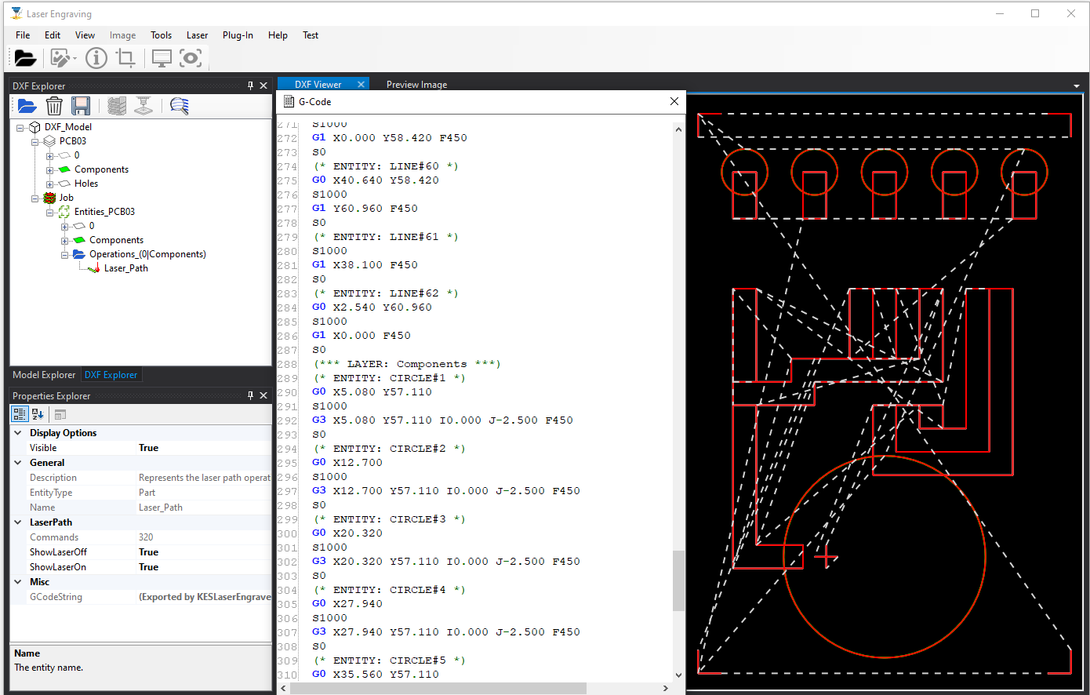

VI - G-Code Inspection

Benefits

The main benefit of the INOVAITEC laser software is the fast and interactive generation of laser tool paths in 2D and 3D. The software has already been used in combination with industrial laser CNC machining from JustLaser France during R&D automotive projects. The results were very promising.

Patterns

Decorative Laser Cutting

Screenshots

Industries: Aerospace Automotive Manufacturing CNC-Machinery Industry 4.0 Smart Factory

Contact

Do you have more questions?

Give us a call on: +49 (0) 176 310 693 62

or send an email to: info@inovaitec.com

We will do our best to answer your questions!