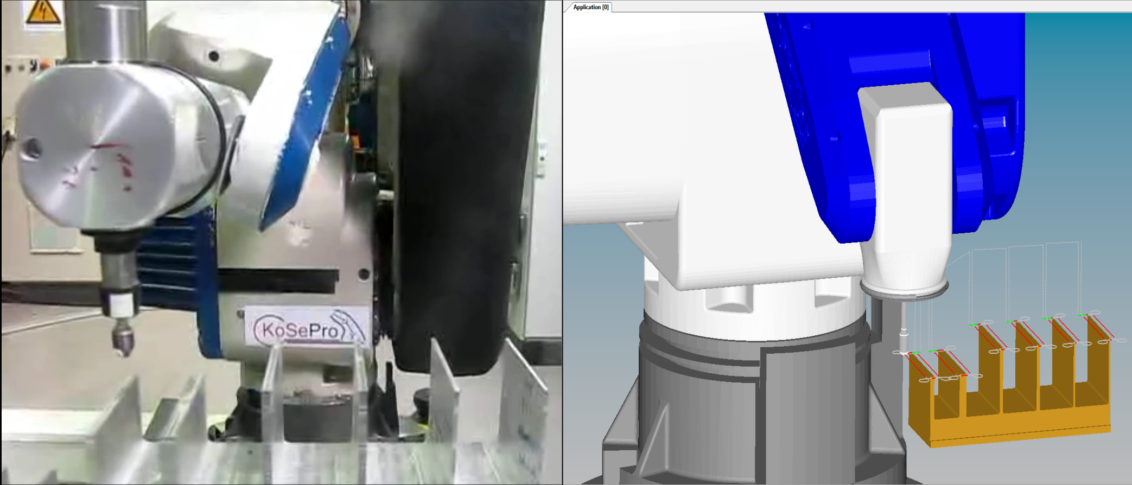

Automated deburring with industrial robots

Automated deburring with industrial robots of metallic workpieces edges

The technology of deburring with industrial robots is used throughout the foundry market in order to precisely, quickly and efficiently remove sprues, runners and other process-relevant excess material after components are cast.

What does deburring mean?

So-called flash or projections can form at edges during the various casting processes. These edges, which can be sharp, may not only impair the functioning of the end product but also increase the risk of injury. For example Thin-walled structural components have an increasing high geometric complexity based on higher technological demands and advanced CAD applications. These components are used particularly in the aviation and aerospace industry.

For this reason, when manufacturing metal parts, these projections must be removed during the finishing process. This technology is referred to as deburring or trimming.

Automated deburring with industrial robots

Industrial robots have the necessary degree of freedom for the tool-movement and the available flexibility for deburring of all sharp workpiece-edges. For this prupose, iNovAITec developed a CAD/CAM-Software, which is able to generate automatically trimmed selections for deburring. This Software was tested with structural workpieces and demonstrates that it is possible to generate small edges on the surface with robots.

Industries: Aerospace Automotive Manufacturing CNC-Machinery

Contact

Do you have more questions?

Give us a call on: +49 (0) 176 310 693 62

or send an email to: info@inovaitec.com

We will do our best to answer your questions!